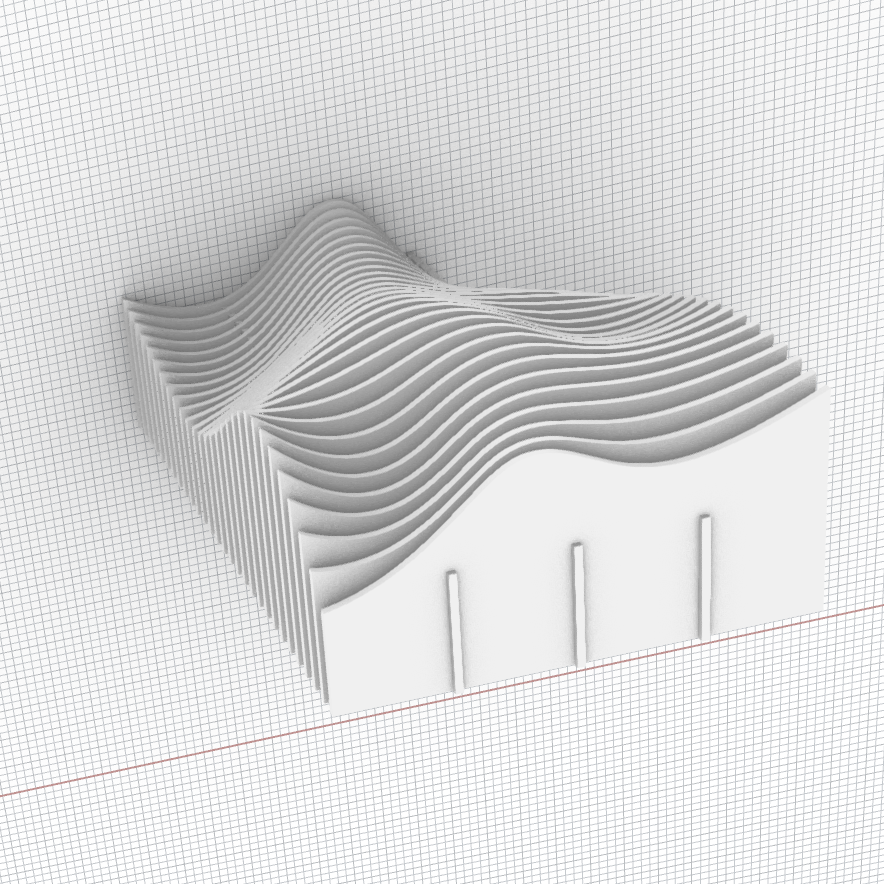

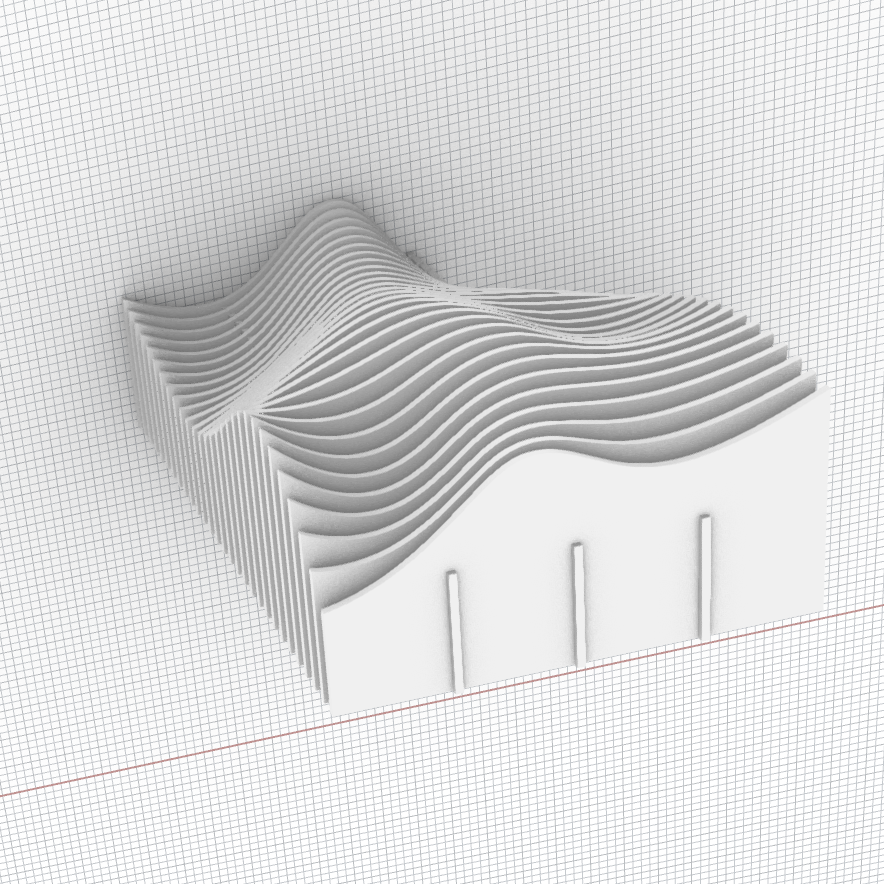

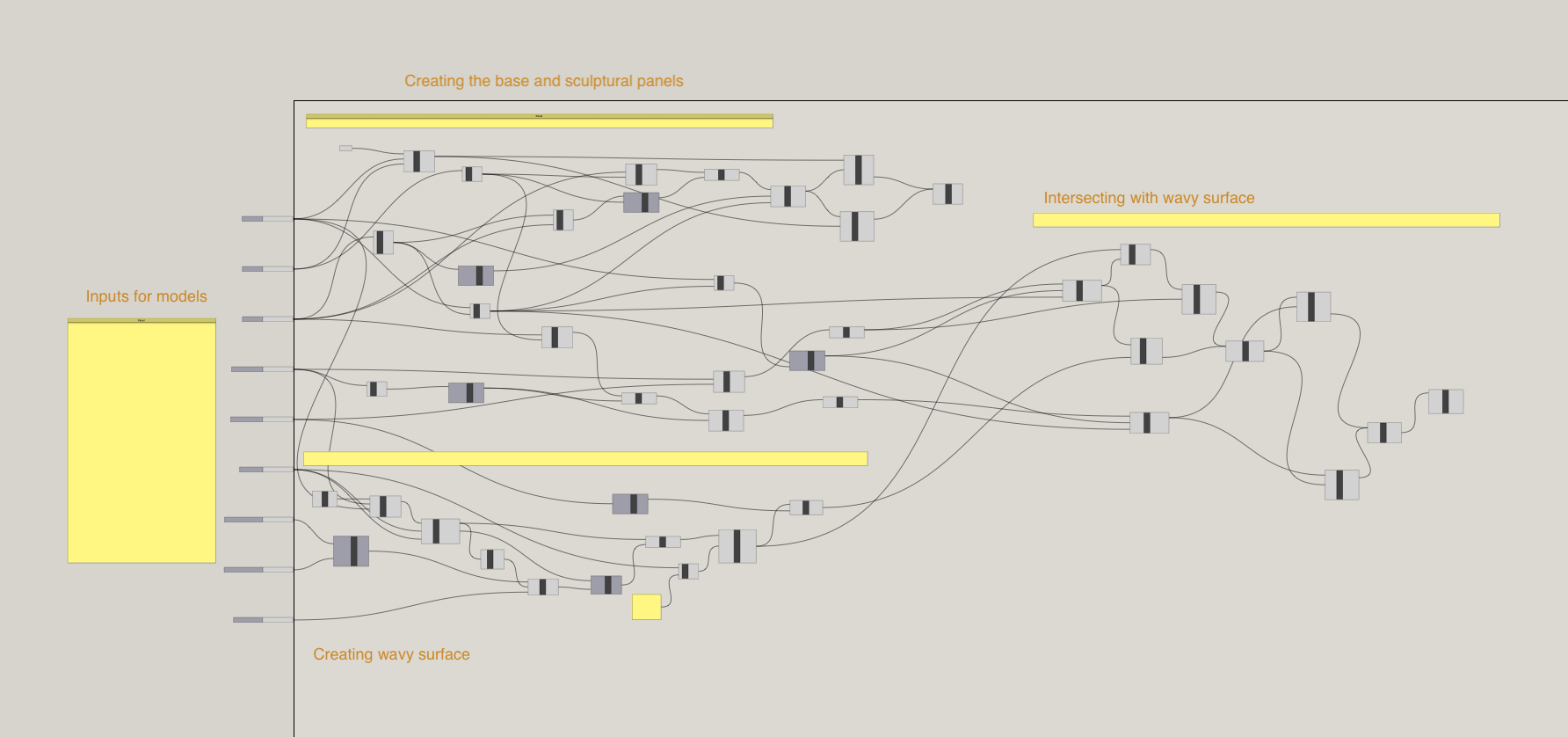

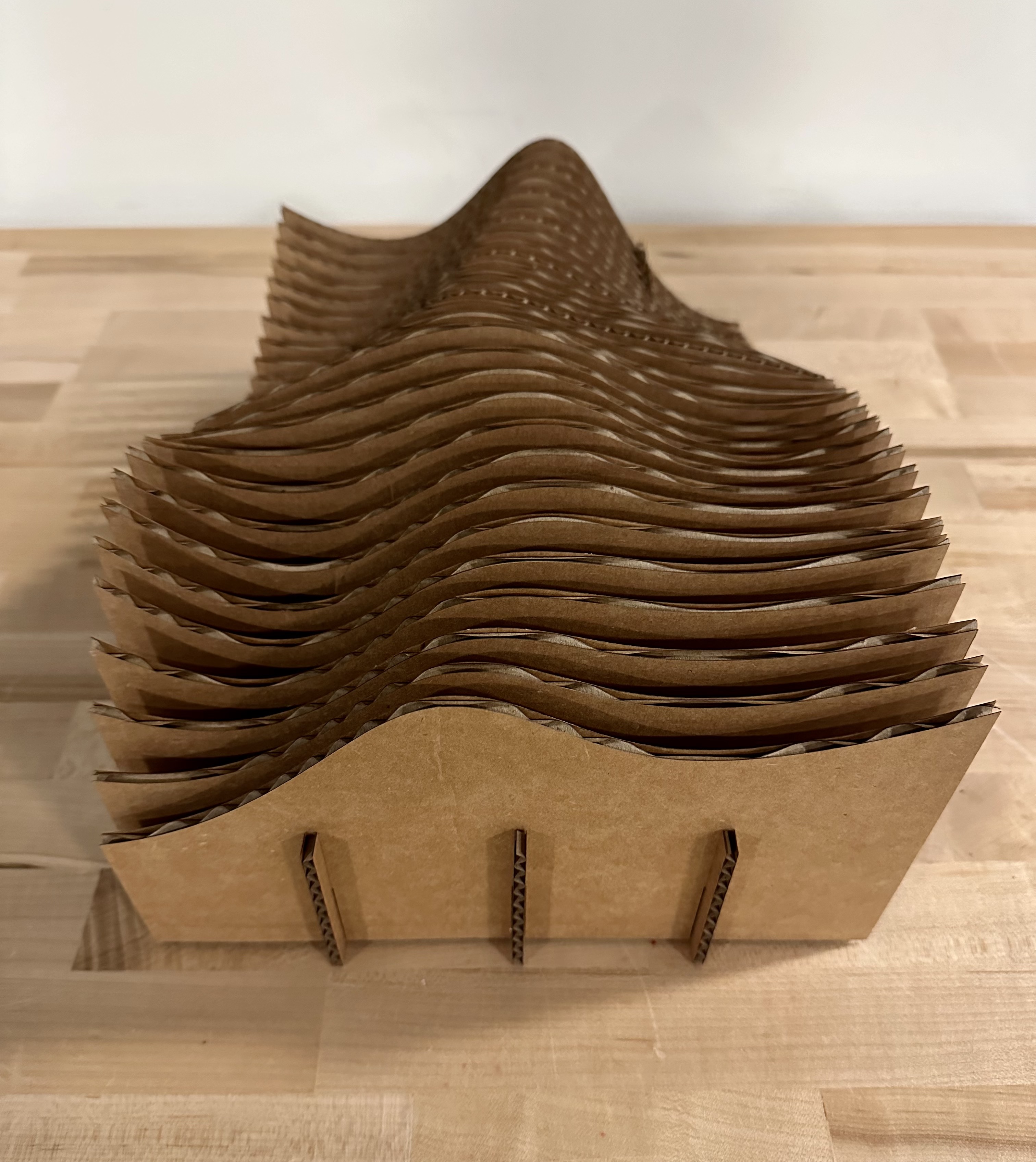

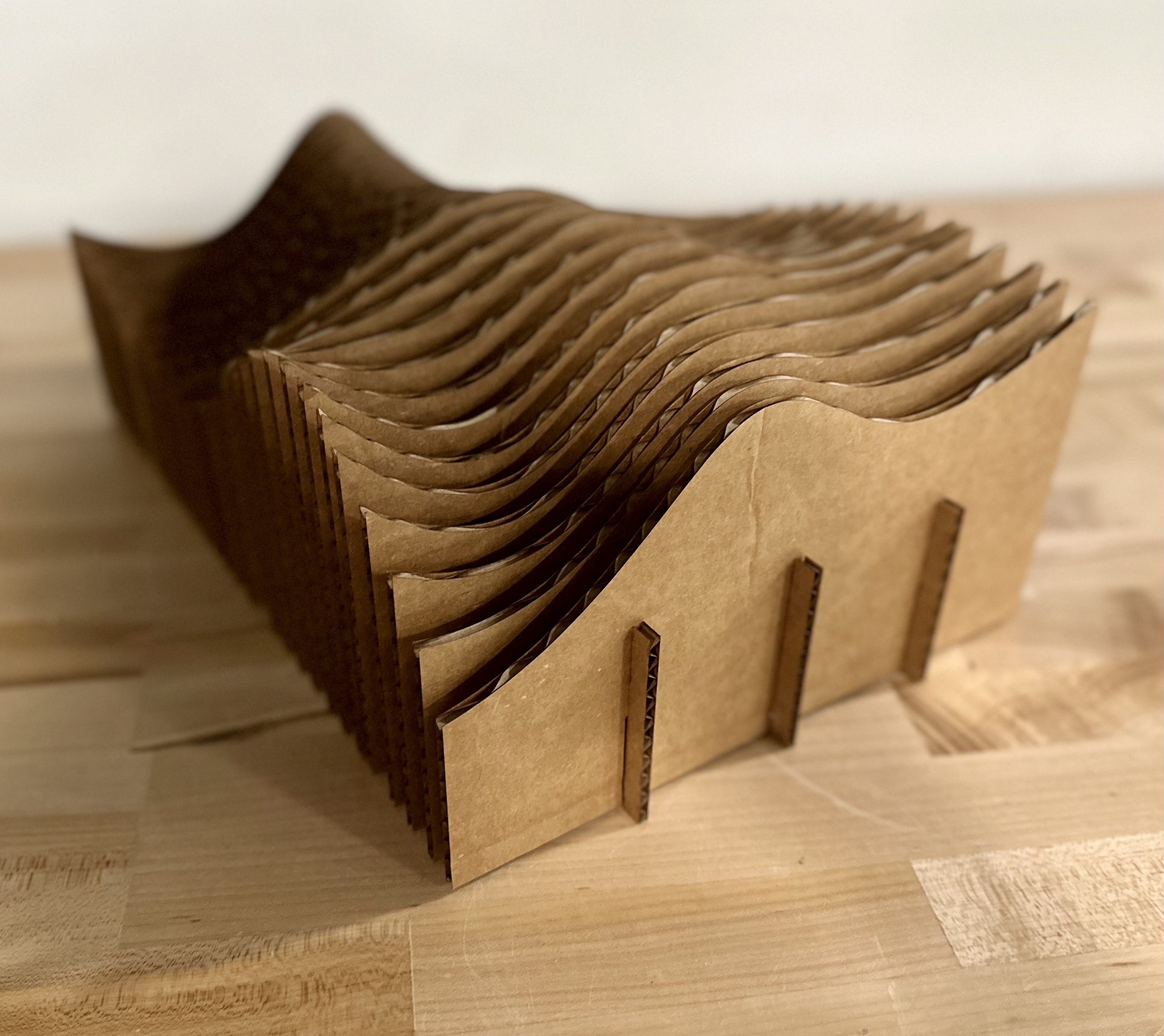

Grasshopper definition

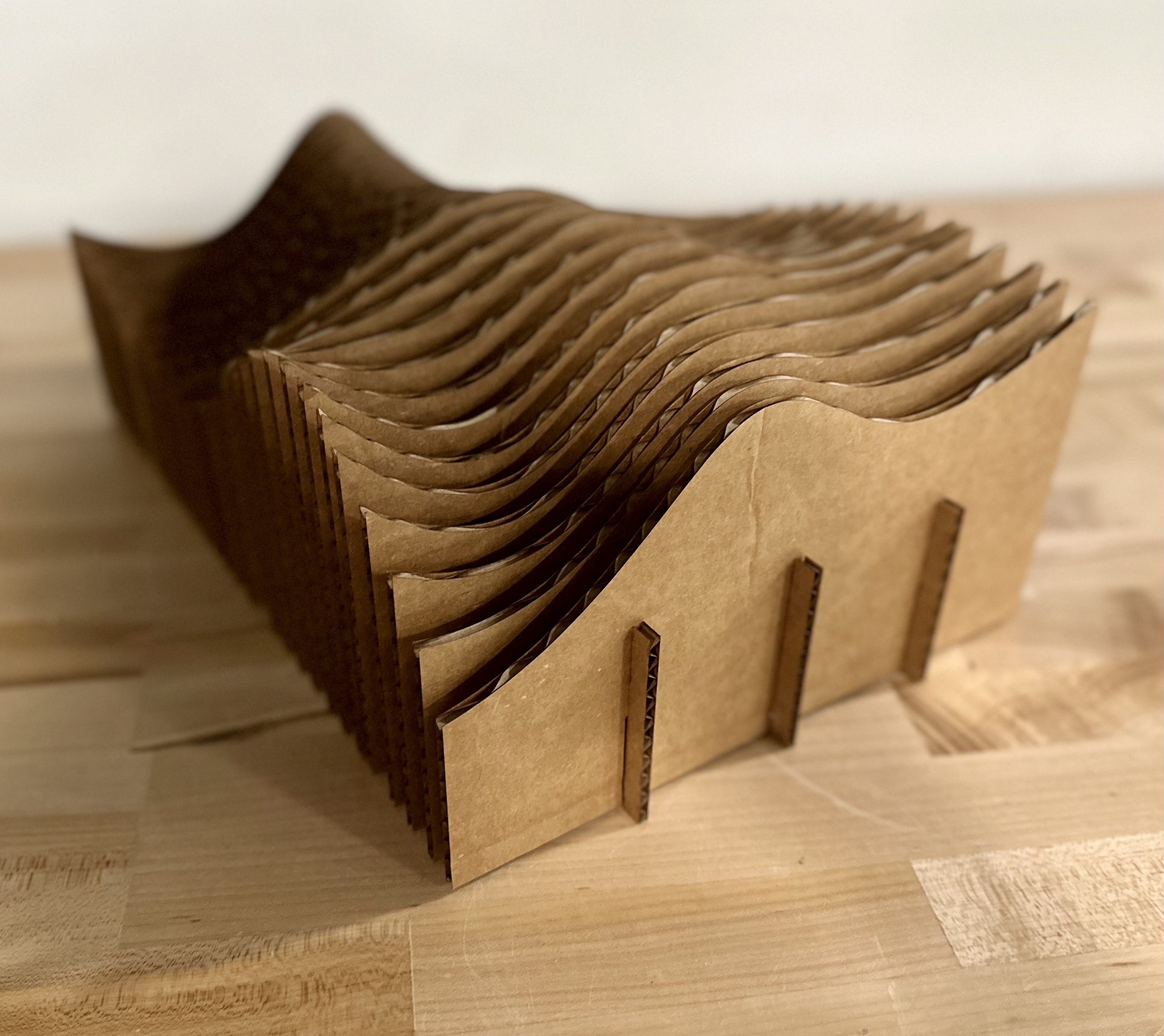

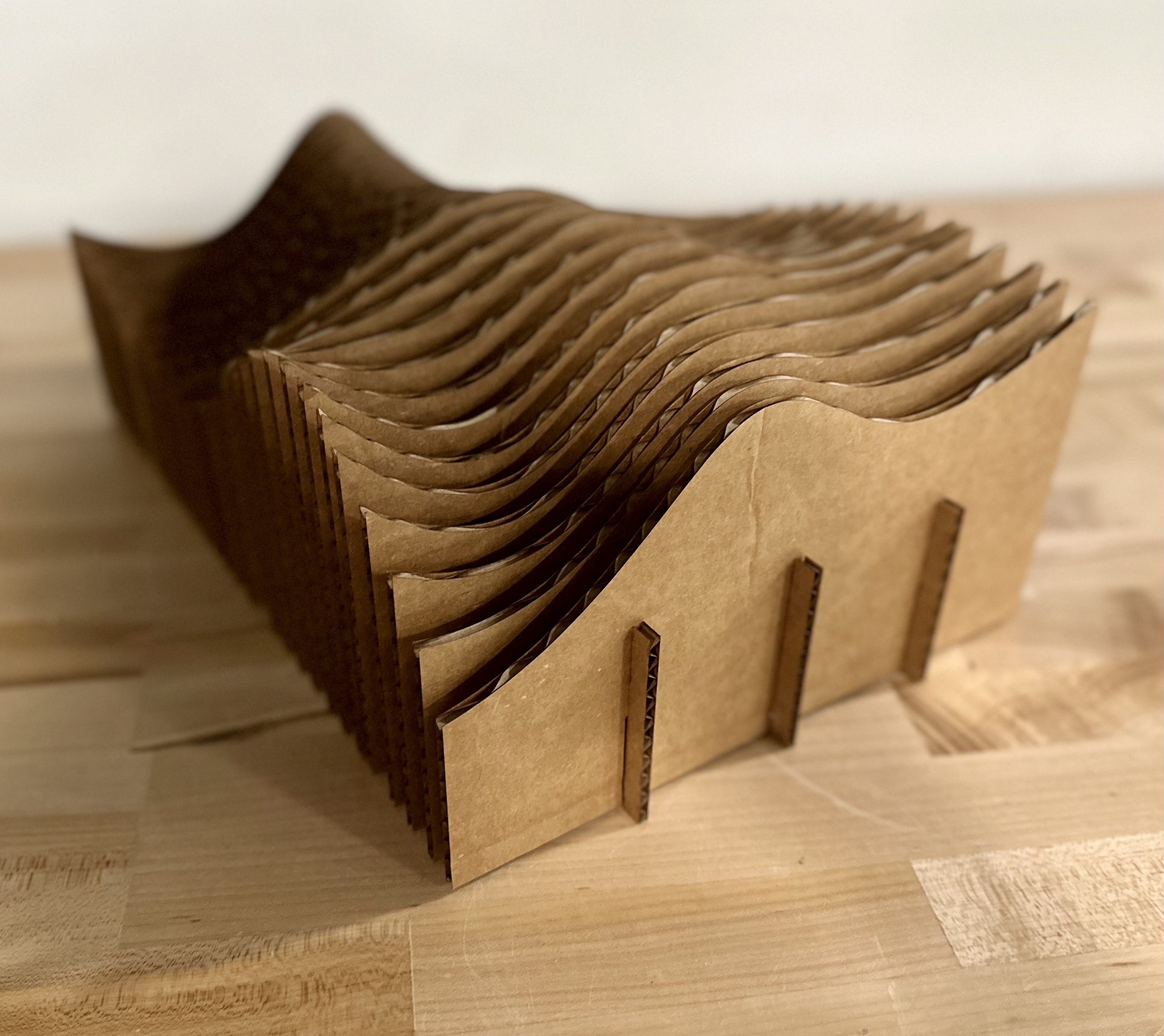

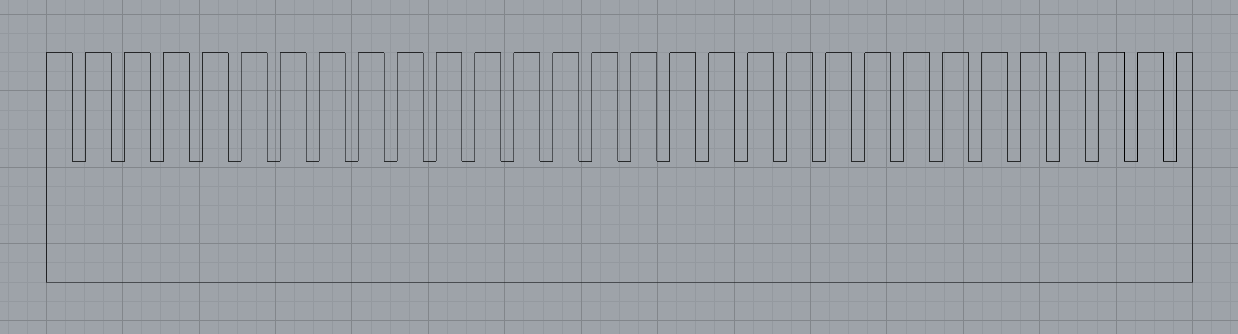

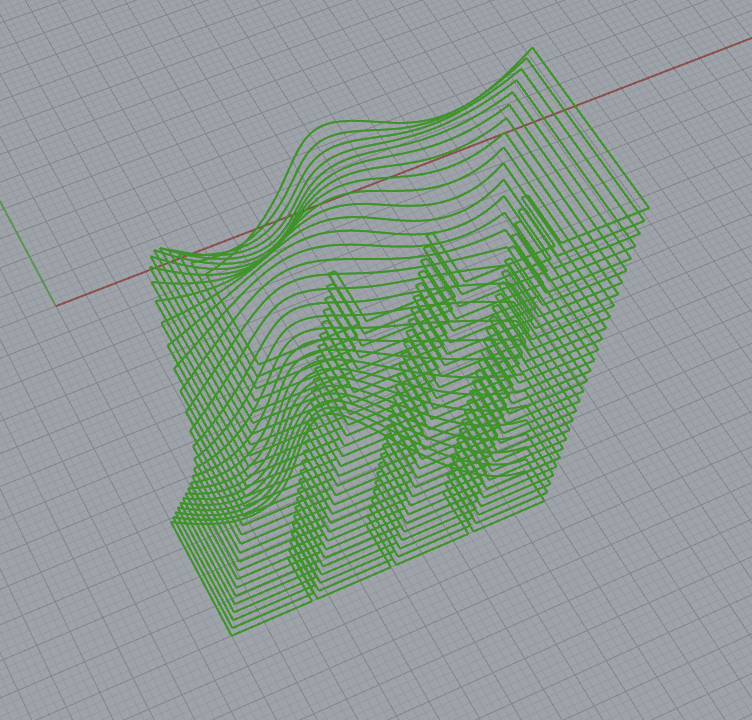

Rhino file (3d and flat)

Illustrator file

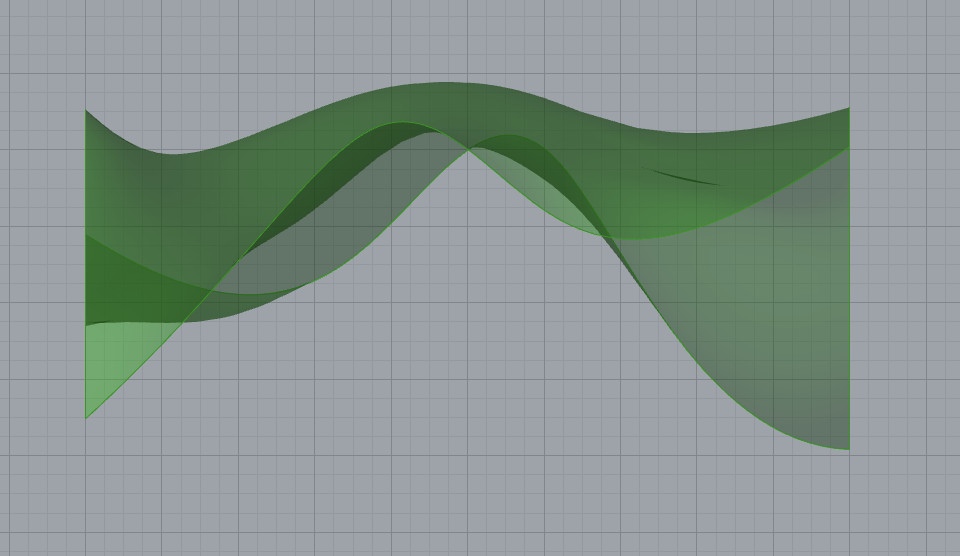

External resources:Wavy surface tutorial

Rhino documentation

Grasshopper documentation

Blog on list actions

Trim/split tutorial

Lots of Rhino forum posts, Grasshopper forum posts, and Reddit posts:

1 , 2 , 3 , 4 , 5 , 6 , 7 , 8 , 9 , 10 , 11 , 12 , 13