Steps

1

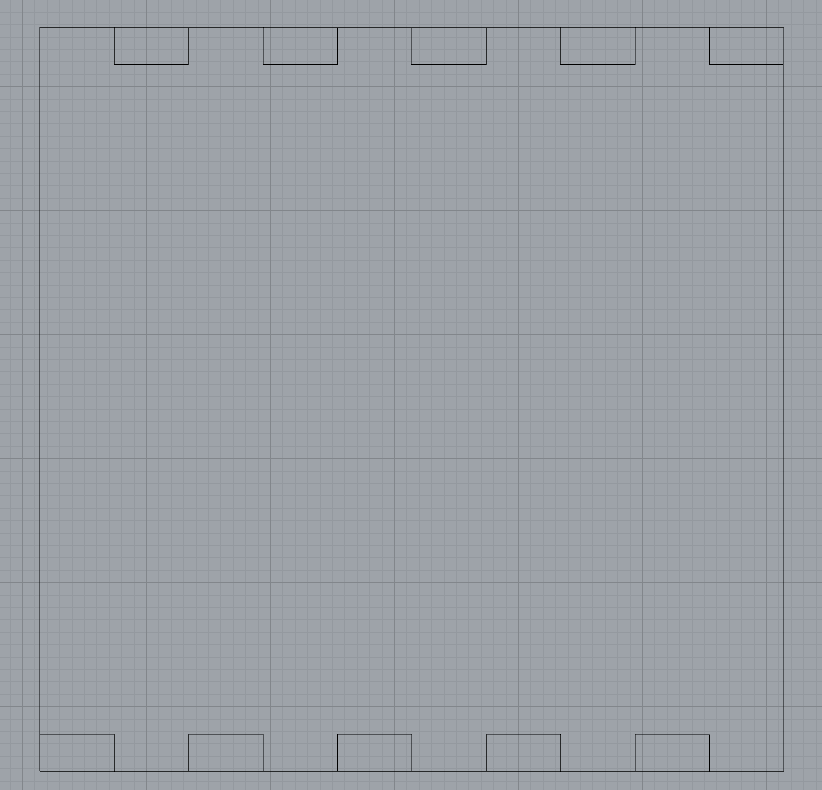

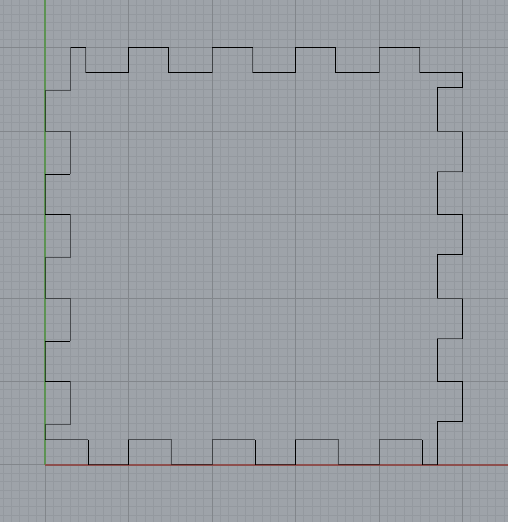

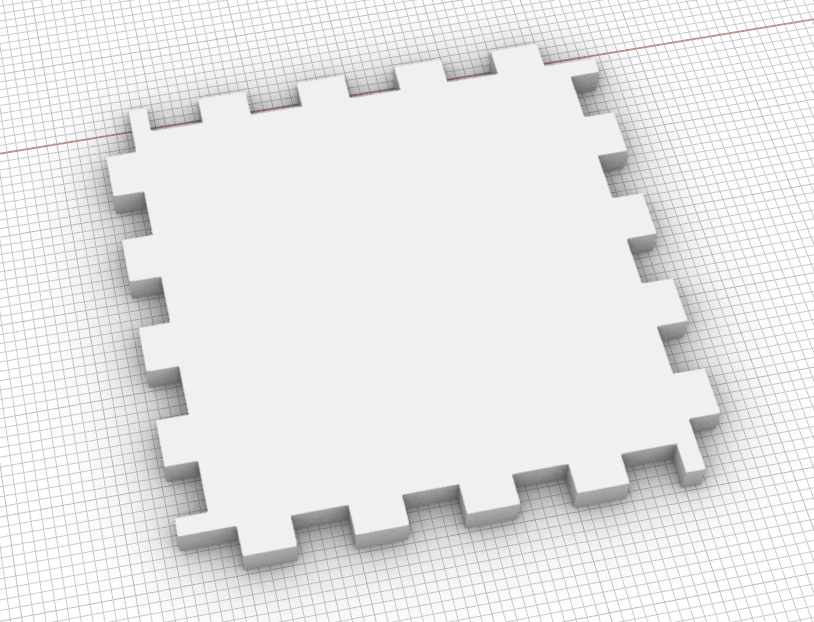

I started off in Rhino with a basic 60mm x 60mm square that I planned to add box joints to. I wasn't sure how they would all fit together in a cube & I was unsure about the fit, so I decided to start with just 2 sides of notches.

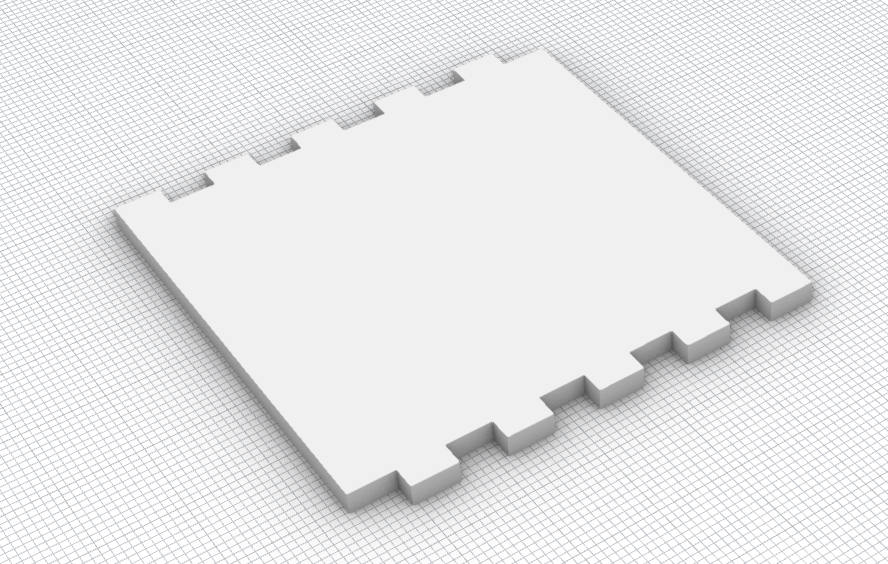

I added equally distributed rectangles along two sides using the linear array function, then trimmed both curves, and extruded to create a model to print.

I added equally distributed rectangles along two sides using the linear array function, then trimmed both curves, and extruded to create a model to print.

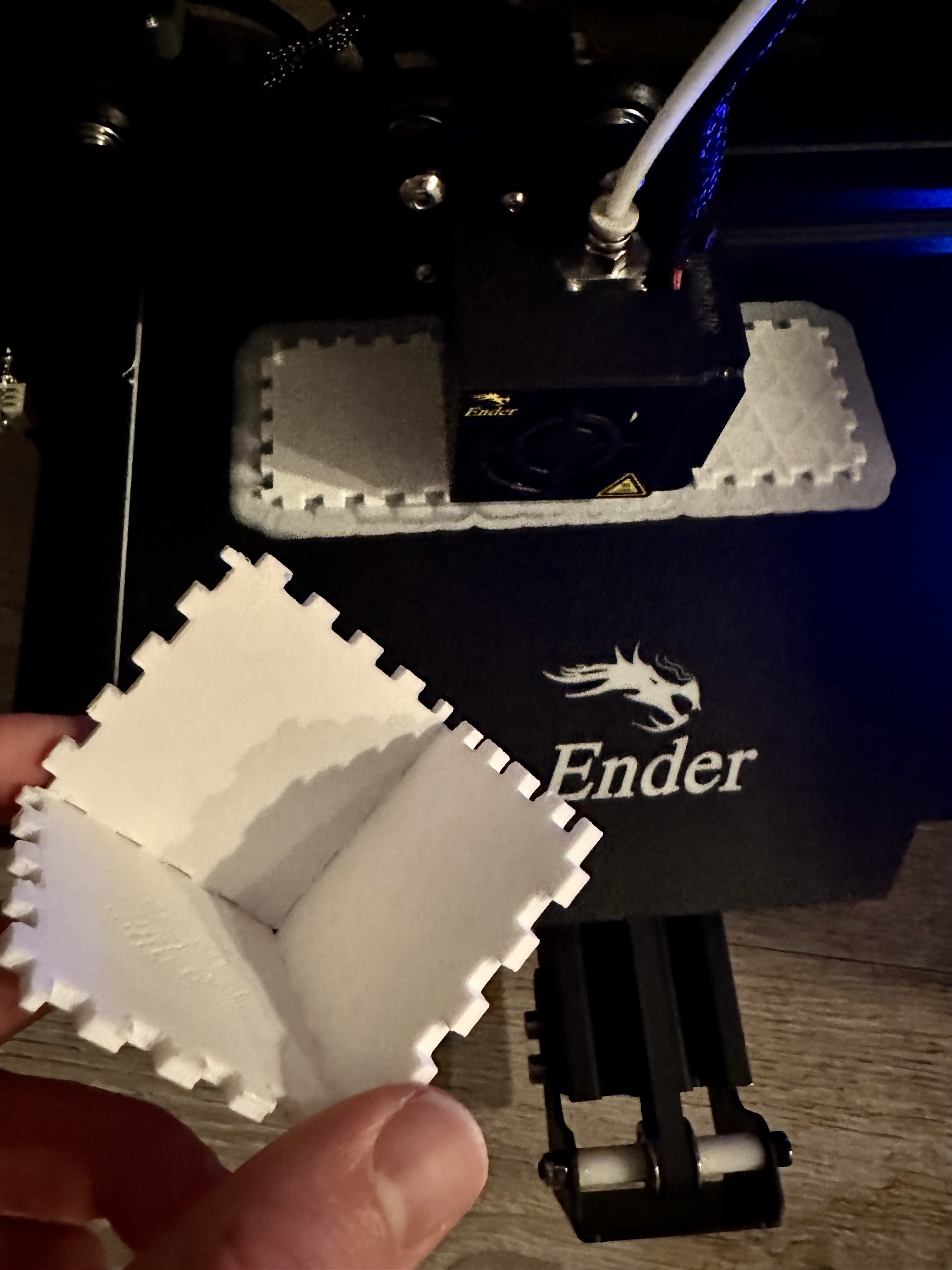

2

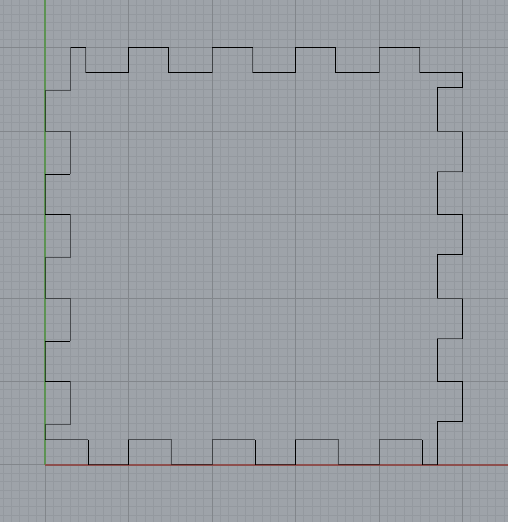

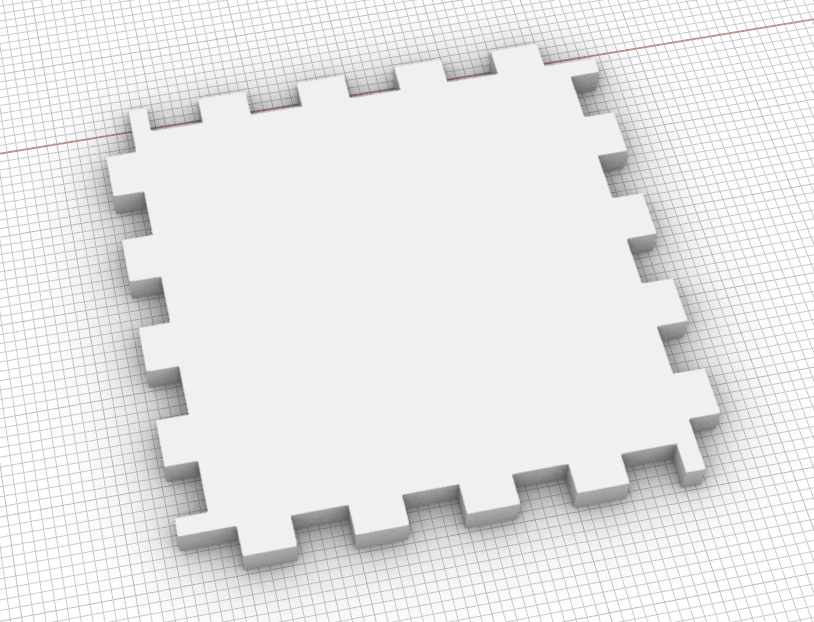

This print was really helpful with 3d visualization, but I found that the equally sized notches and rectangle pegs did not fit well considering the precision of the machine. The second time around, I updated the rectangular pegs to be 4.8mm and the notches to be 5.2mm so that there would be +- 0.4mm of wiggle room for pushing the pieces together.

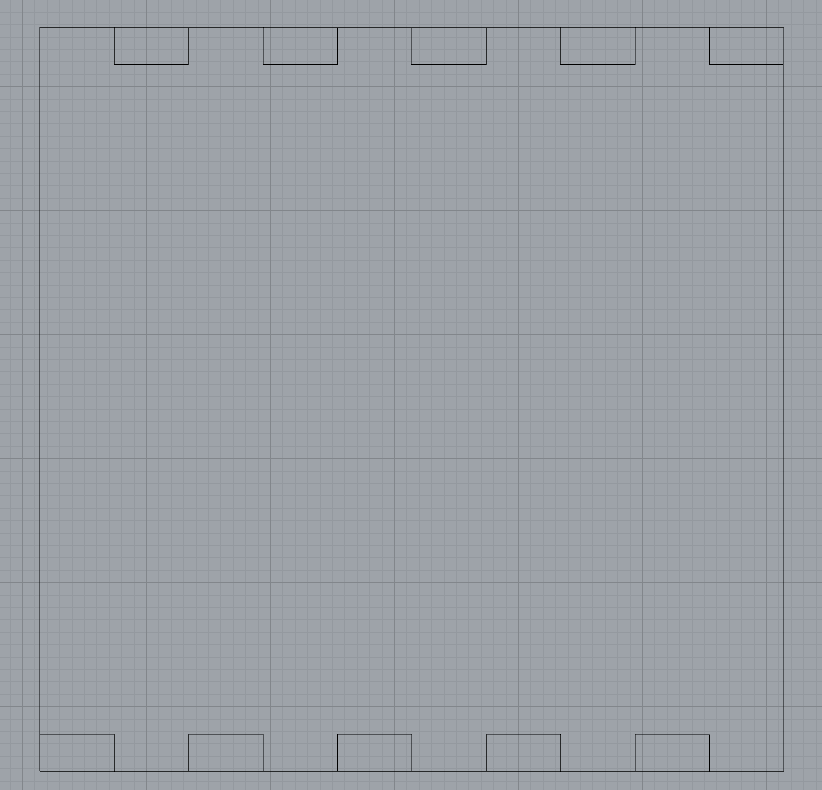

I followed the same process as above, but this time with all 4 sides notch-ified:

I followed the same process as above, but this time with all 4 sides notch-ified:

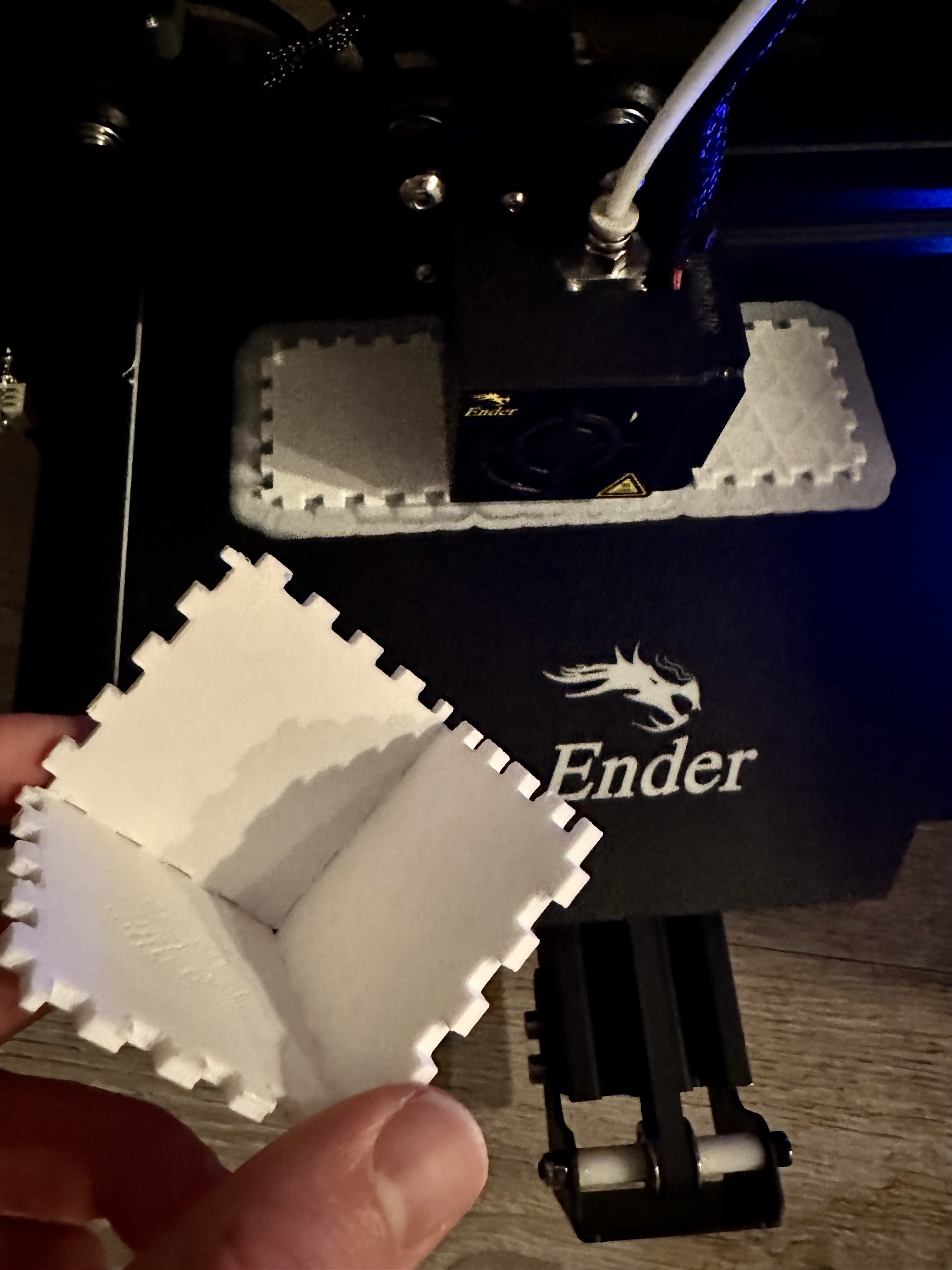

3

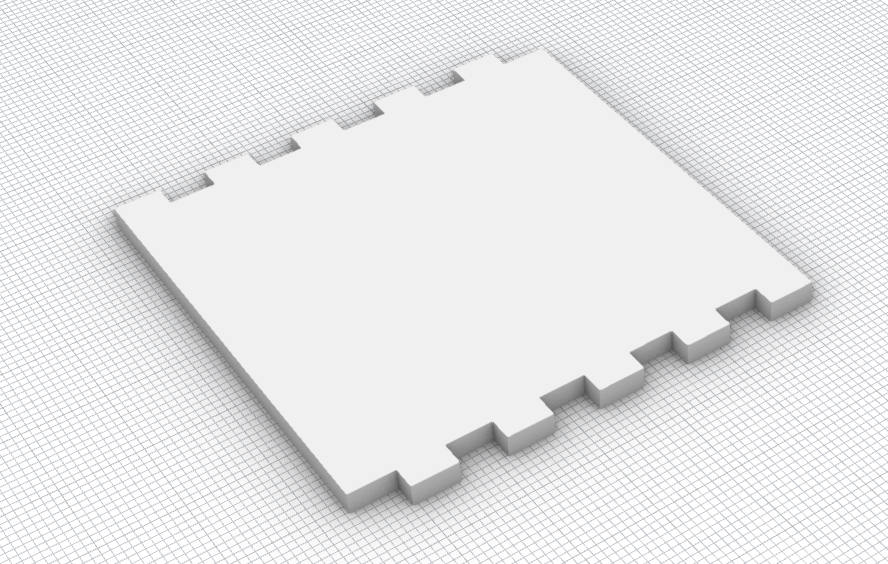

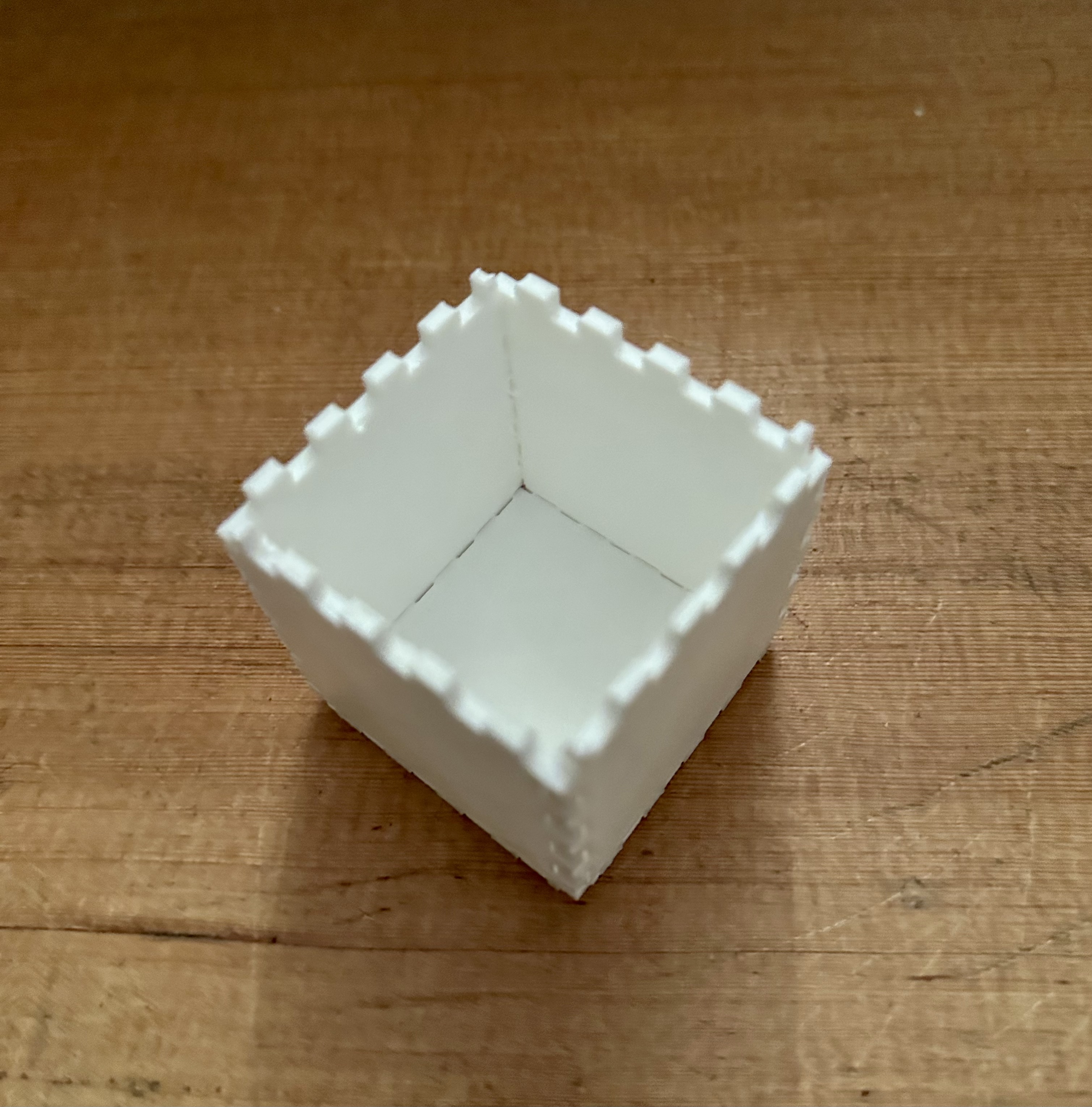

This worked much better! I printed 3 at first to make sure that it would work in a the corner, and I was happy with the result. The biggest struggle was getting all of the adhesive base out of the notches.

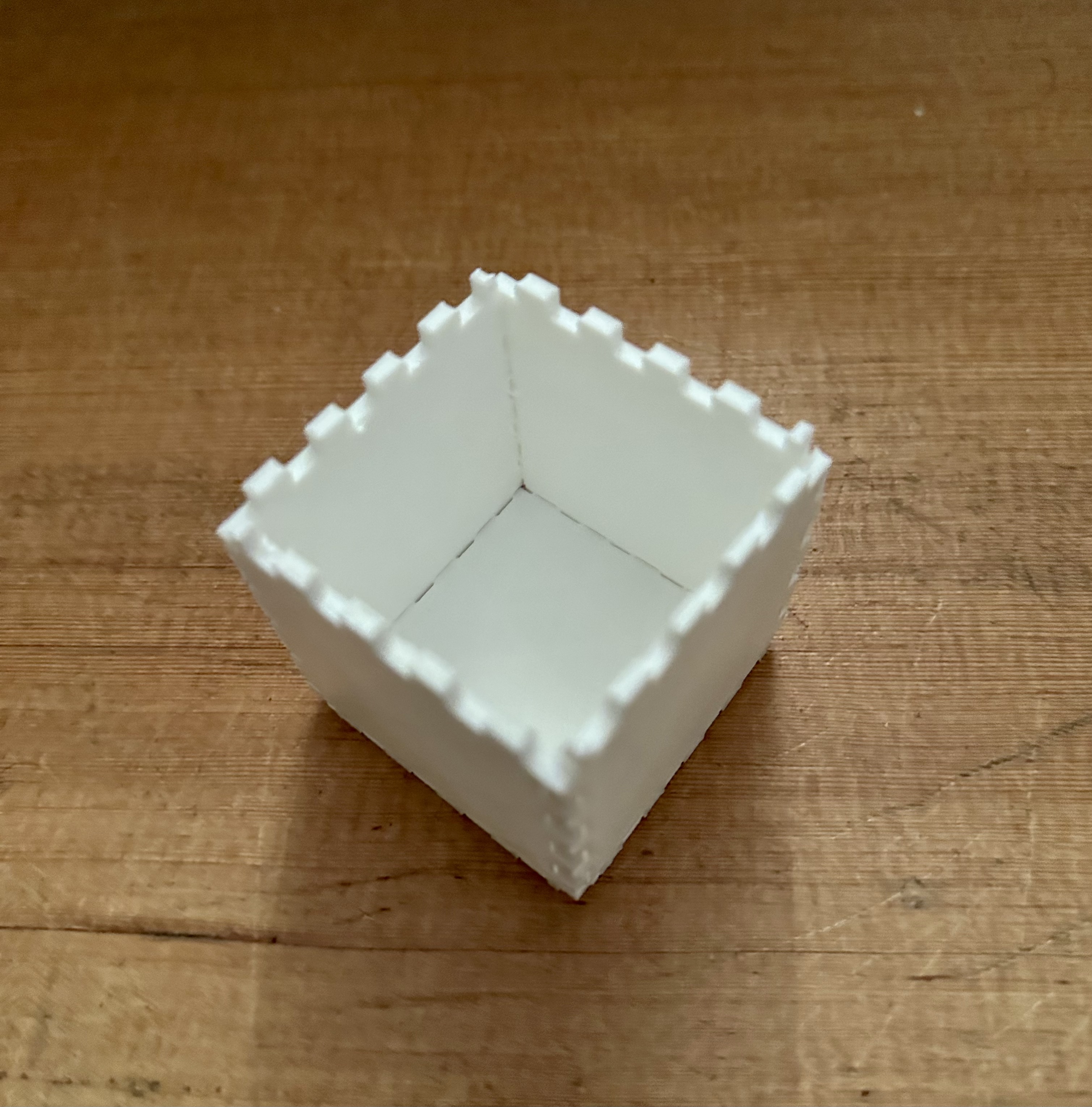

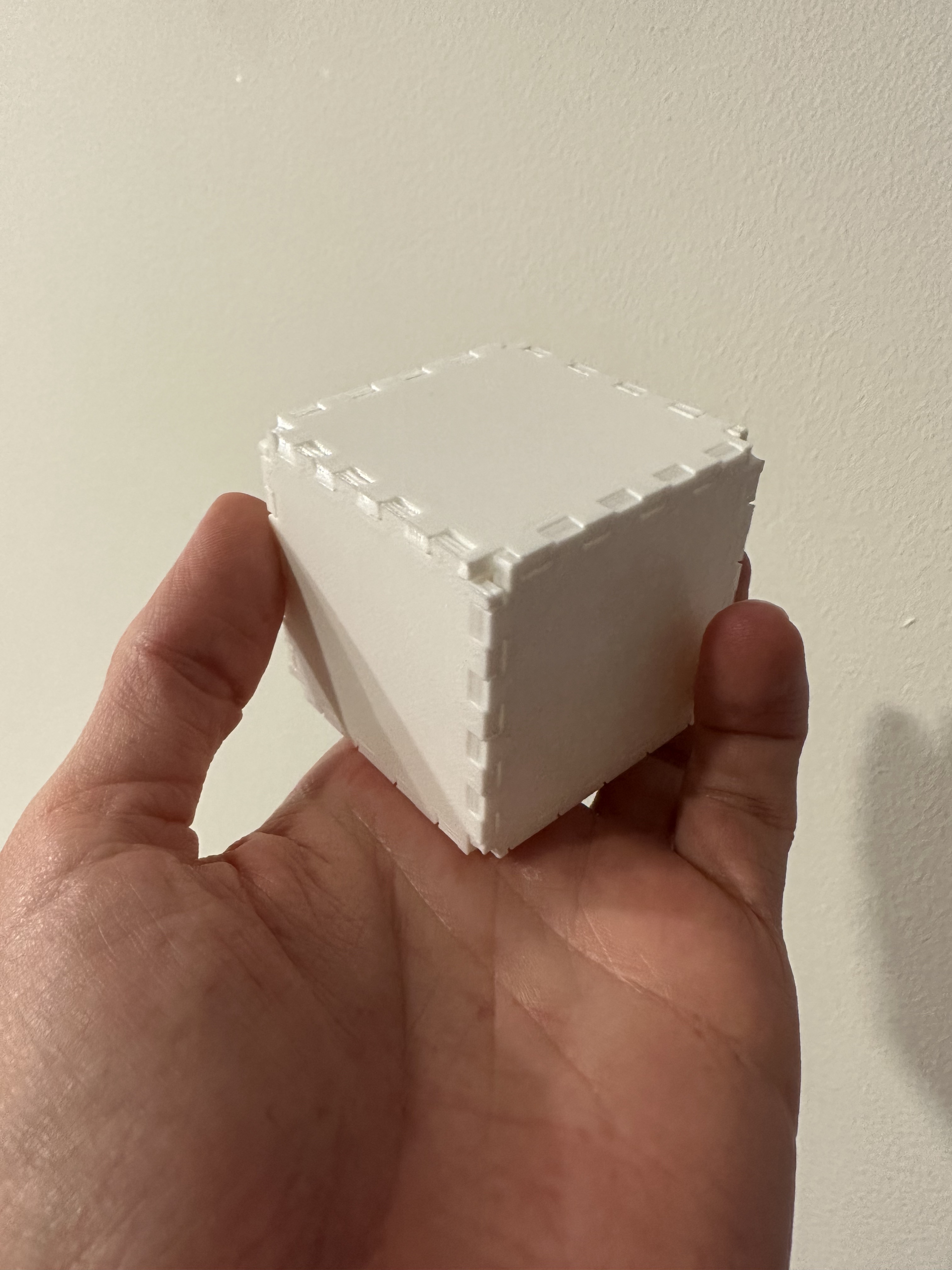

4

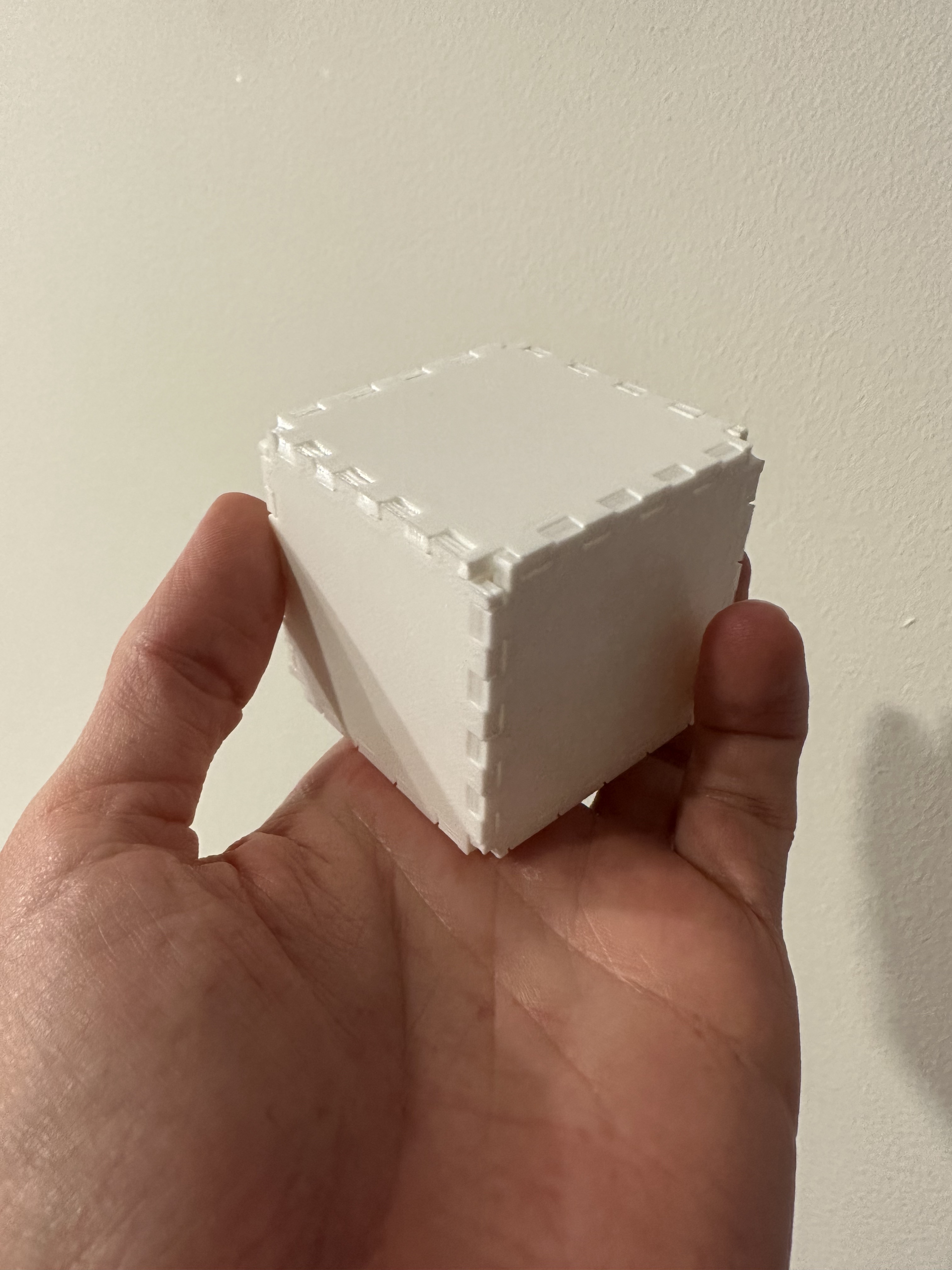

After testing out the first 3 sides, I printed the other 3 sides to make a cube, and snapped them all together! It was very satisfying having them all fit and stick together well.

Resources

My creations:

Panels 3dm

Panels stl

External resources:Video conversion

Learning about inside corners

Thanks to the various posts in the Discord channel for the help understanding notches / fit! Especially for posts from Junchao.