Steps

For the final project, I'm planning to parametrically design patterns for a tailored shirt, laser cut those patterns from fabric, 3d print designs onto the fabric, and then sew the shirt.

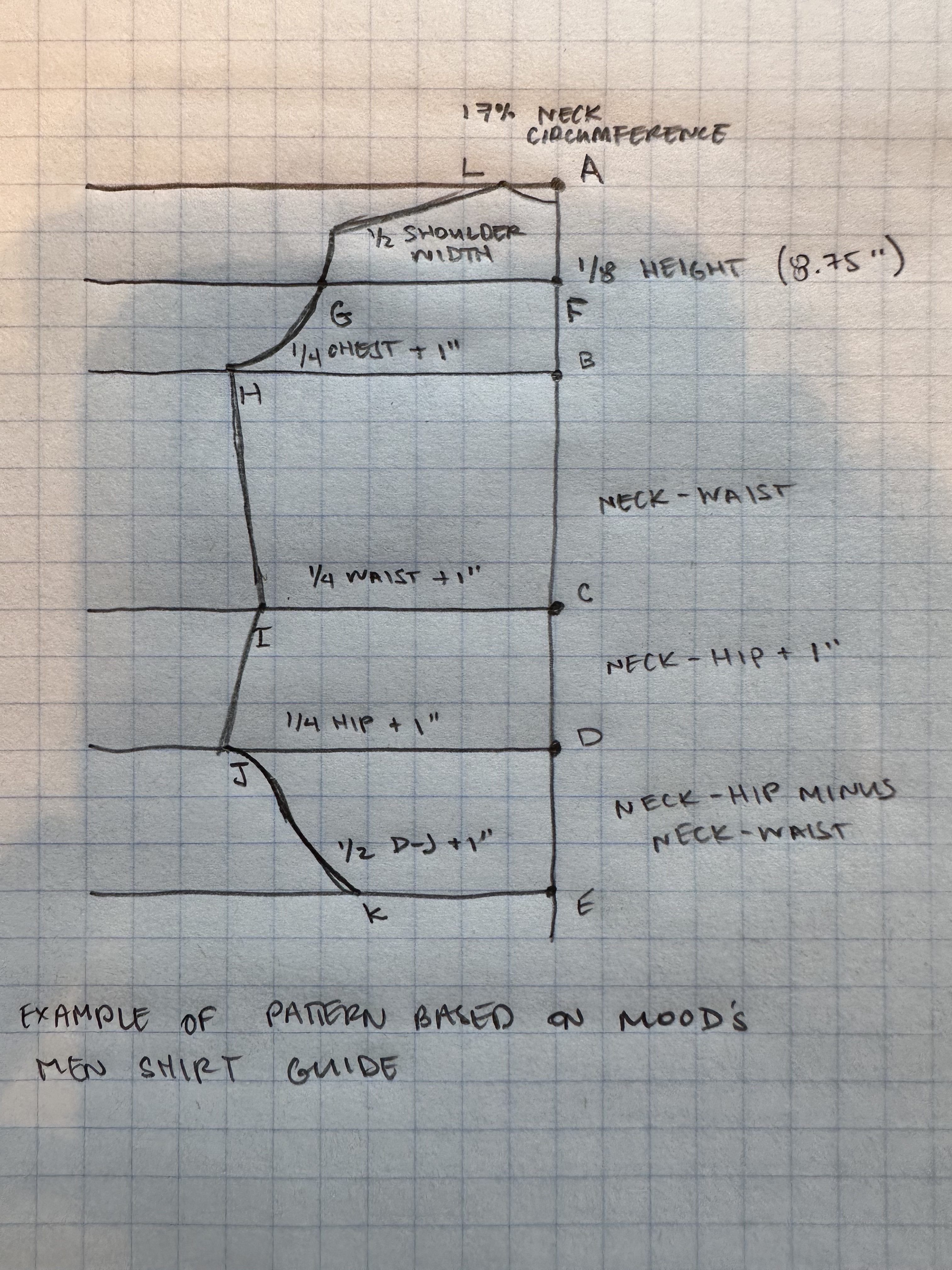

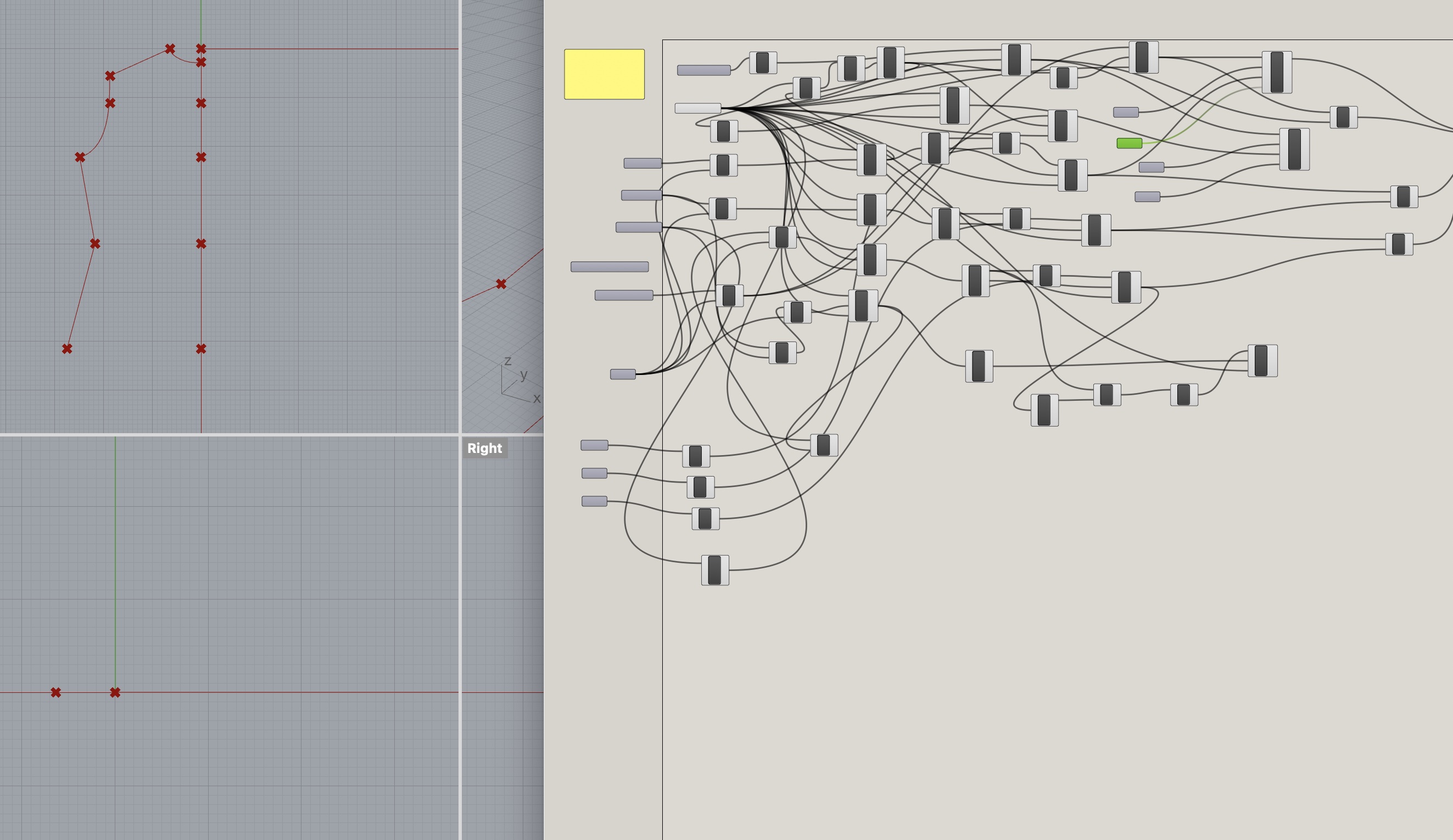

- create Grasshopper defintion for front/back panels, sleeves, and collar following the Mood fabrics drafting tutorials

- create the Rhino 2d model of patterns and use them to laser cut the fabric if possible, or pattern pieces if not, or hand cut if laser cutter is not available

- create Rhino 3d model of design to be printed on shoulders of the fabric (design to be determined)

- print 3d models onto fabric, fabric glue if necessary

- sew pattern!

| Date | Plan | Contingency/disclaimer |

|---|---|---|

| 11/25 | Draft of pattern pieces ready in Rhino from Grasshopper definition | Design is preliminary, may change based on aesthetic and functional decisions |

| 11/27 | Test 3d printing onto final fabric | If 3d print on fabric does not stick, will use fabric glue to attach printed pieces |

| 11/28 | Test laser cutting fabric / pattern pieces | If laser cutter is unavailable for any reason, will cut by hand; if laser cutter can't cut fabric, will cut paper pattern pieces |

| 11/30 | 3d model to print is done, tested on fabric | - |

| 12/1 | 3d printing onto fabric is complete, sewing begins | - |

| 12/2 | Construction in progress, write up remaining | - |

| 12/6 | Project done! | - |

| # | Item | Location | Est. price |

|---|---|---|---|

| 1 | Fabric | Pacific Fabrics | $20-40 |

| 2 | Thread | -already own- | -already own- |

| 3 | PLA filament | -already own- | -already own- |

| 4 | Pattern paper | Blick's | $5 |

| 5 | Buttons | Pacific Fabrics | $5 |

Resources

nothing yet...

External resources:3D printing on fabric

Create a text object in grasshopper

inch to mm - Google Search

Curve Derivatives

Grasshopper Curve - Addon for Grasshopper

Tips and Tricks for Advanced Curve Modeling in Rhino

Which command to best fit a smooth curve through a scattering of points?

Finding the point with the lowest X and Y value

3D Printed Fashion: The Top Designs

HTML Tables

Git Config - How To Use Git Config | W3Docs Git Online Tutorial

Three Ways to Attach Boning

Boning - Types and Sewing Tips -- CreateForLess

How to Sew a Men's Shirt

3D Printing on fabric is easier than you think! – Geeetech

How to 3D Print Onto Fabric

How to Measure Yourself for Sewing and Why

Drafting a Men's Shirt Pattern Part 3

Drafting a Men's Shirt Pattern Part 2

Drafting a Men's Shirt Pattern Part 1

Zotero

CSS-TRICKS

GeeksforGeeks

W3C

W3 schools

Thanks to the various posts in the Discord channel for the help!

Also thanks to Sara Cagle for ideas about laser cutting fabrics.